Surface Technologies

Unilin Technologies has dedicated several years to developing and patenting surface technologies.

The surface technologies provide certain technical advantages. In addition, textural surfaces improve the appearance of the floor and give each design its unique wooden authenticity. Surfaces can be produced by different processes.

Compressed wood technology

The compressed wood technology improves the integral strength of the wood while reducing the wear damage. After the wood has been processed it retains its original appearance and grain texture, but has become stronger. As an example, impact resistance and wear resistance of an oak veneer treated with this technology can improve between 20-40% compared to an untreated veneer. Besides increasing the impact and wear resistance, the compressed wood technology also considerably improves the stability of the wood.

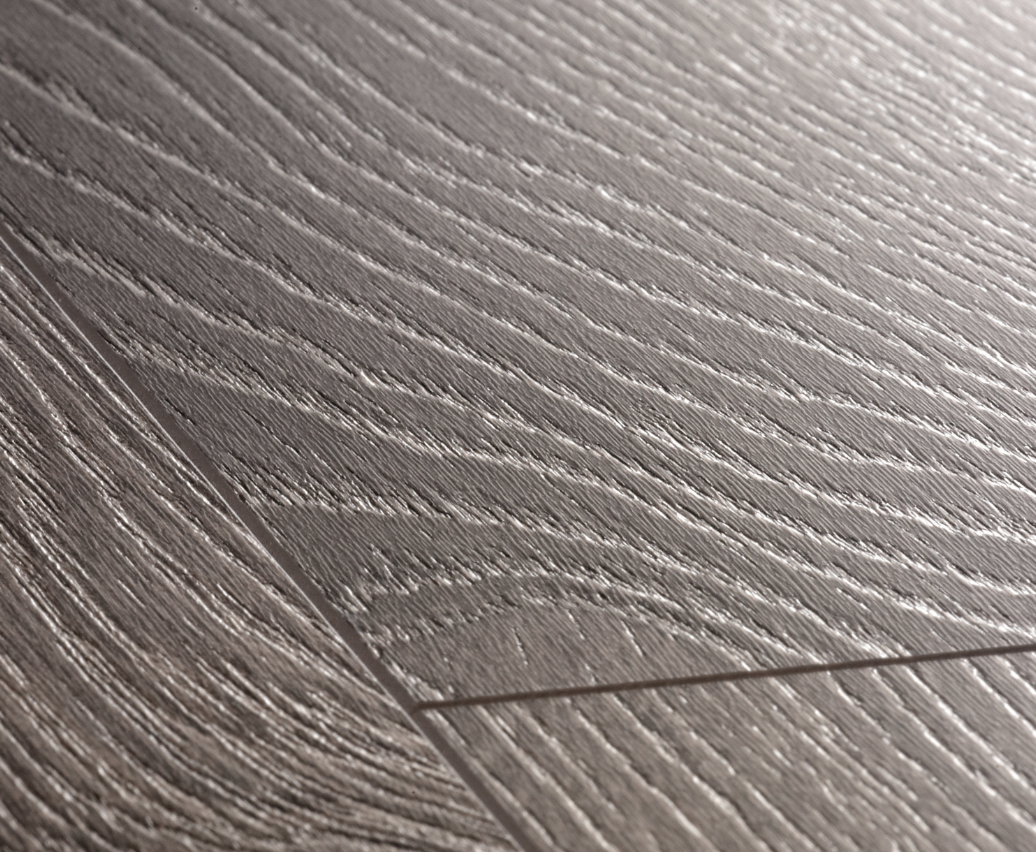

Embossed in register

True-to-nature surface structures are created by means of the press plates used in the lamination process, giving the planks a realistic texture that matches the decor.

Deep embossing/scraped

The MDF board of the floor panel is deformed to create deep structures, imitating scraped wood, cracks, gaps and beveled edges found in real wood planks.

Gloss-matt contrast

This technology enables the creation of surface structures with different degrees of gloss finish that are in register with the print of the floor. Wood species such as "wenge" can be imitated very reliably.

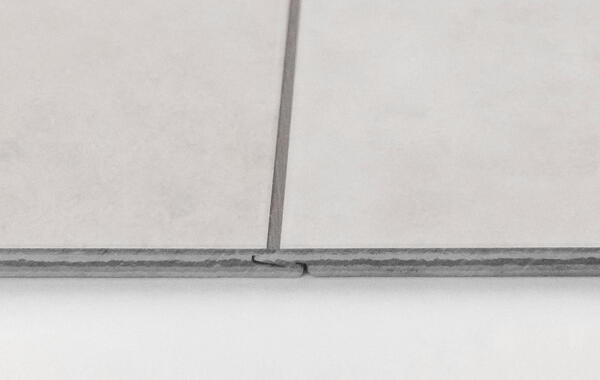

Anti "white line" technologies

This technology masks white lines originating from cutting the melamine top layer of floorings. This is done by using laser cutting technology or by coloring the edge of the cut floor in the milling line. Unilin has entered into a cooperation agreement with the company Berry-Alloc in order to increase the patent protection on this technology.