Bevel Technologies

Unilin Technologies provides several bevel technologies to enhance the appearance of your flooring products.

Enhance all flooring products by giving them a high end plank effect by using and combining several techniques.

Unilin invented and patented a complete range of bevel technologies that are made available to their licensed partners.

- Grout solutions

- More natural look

- Pattern imitations

- Different depths

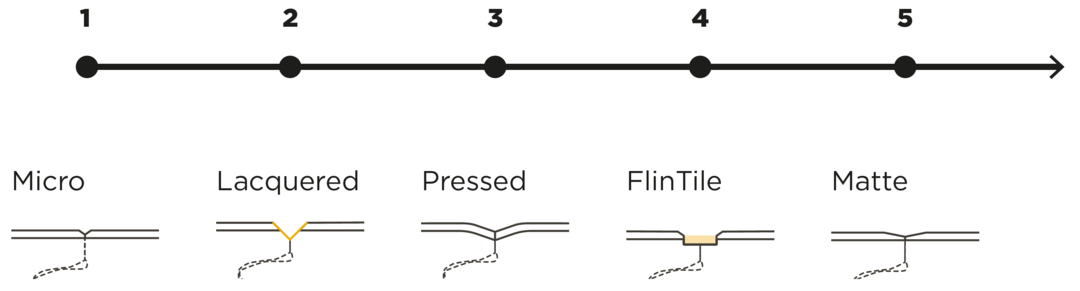

Generations of bevel technologies

Improve the look, feel the groove

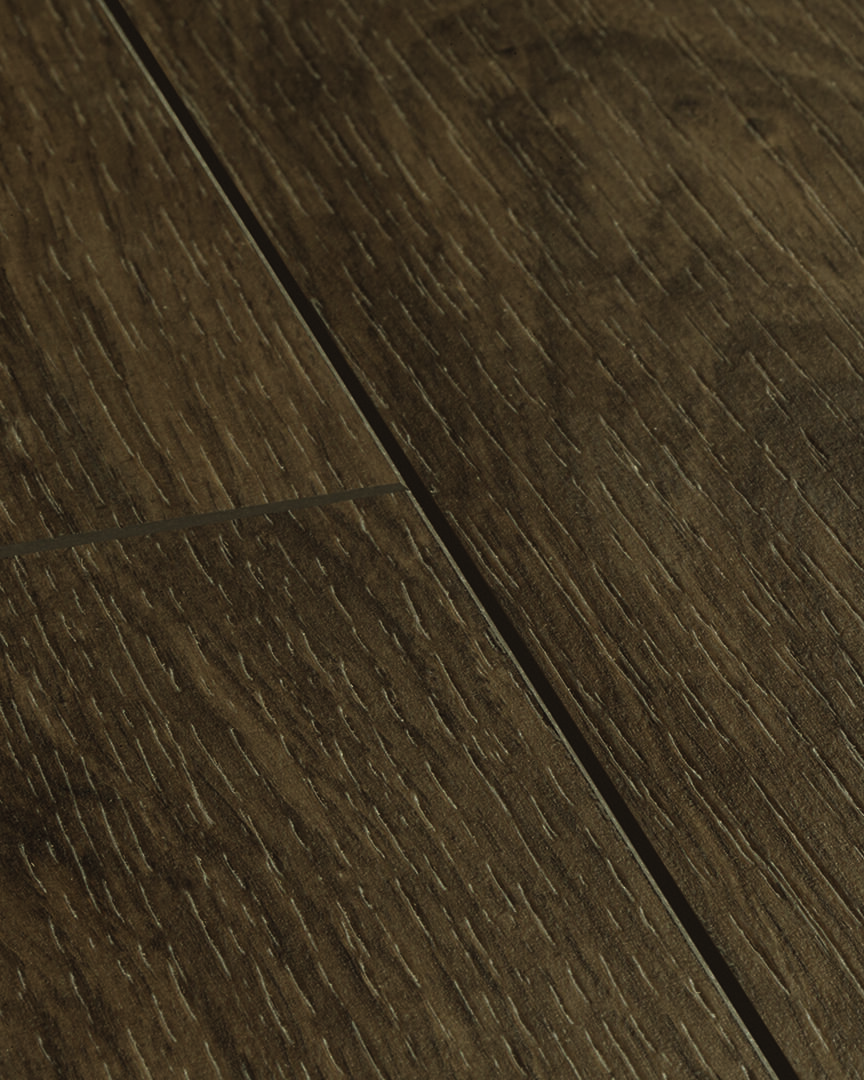

Bevels can really change the look and feel of flooring products.

Throughout the years, the bevel has evolved in different stages together with the market trends and technical possibilities.

The choice of the bevel type can give floors a more natural look, close to real wood products, and can elevate a floor to the next level of authenticity.

Herringbone pattern imitations, different lacquers to highlight the joints, and even grout solutions - a bevel can have many different functions.

By pioneering bevel technologies since 2001, Unilin creates more design versatility and practicality for flooring producers.

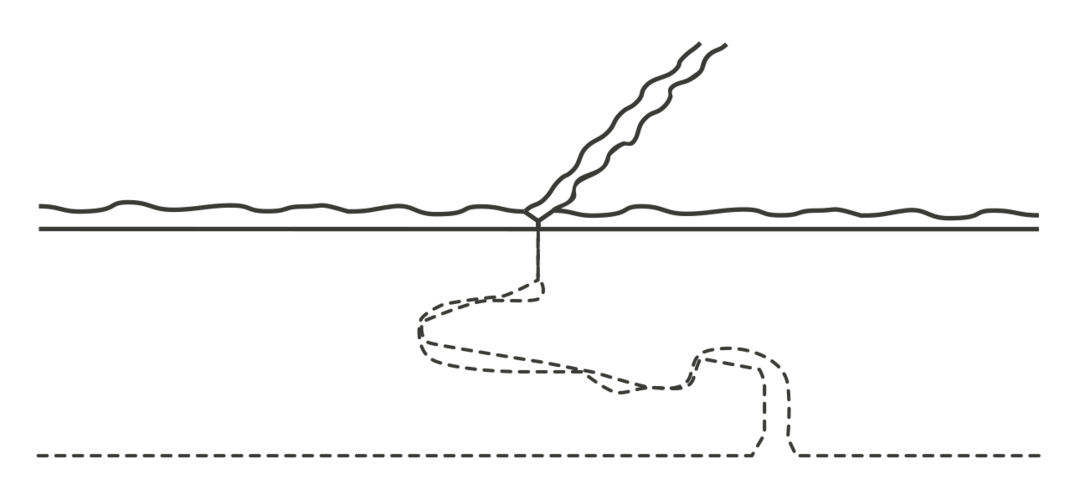

Generation 1 - Micro Bevel

Micro Bevel

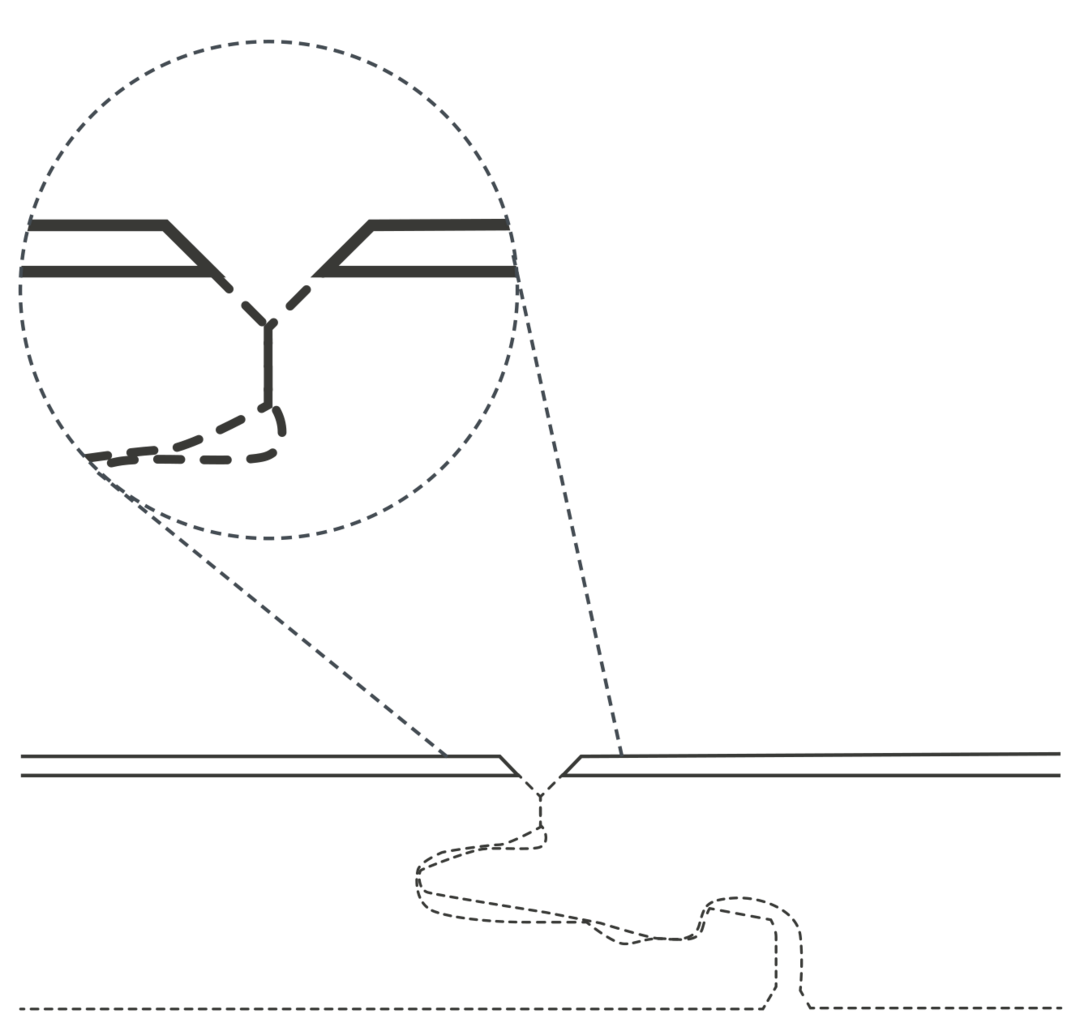

This bevel edge is created by milling away part of the wear layer of the floor panel in a shallow angle.

This Micro Bevel gives a fine, thin bevel effect.

Unilin invented and patented this technology already in 2006.

Over the years Unilin licensed it out and today this technology is widely spread and used all over the world.

Generation 2 - Lacquered Bevel

Lacquered Bevel

The lacquered beveled edge is created by milling away part of the top of the floor panel (deeper compared to Micro Bevel).

A lot has happened since Unilin patented the first lacquered bevel technology in 2000.

Lacquering has evolved and different techniques are used such as vacuum application, and even digital printing technology.

Bevels can be accentuated by choosing a matching or contrasting color. The technology evolved to incorporate the middle snit milling for tiles or herringbone simulations.

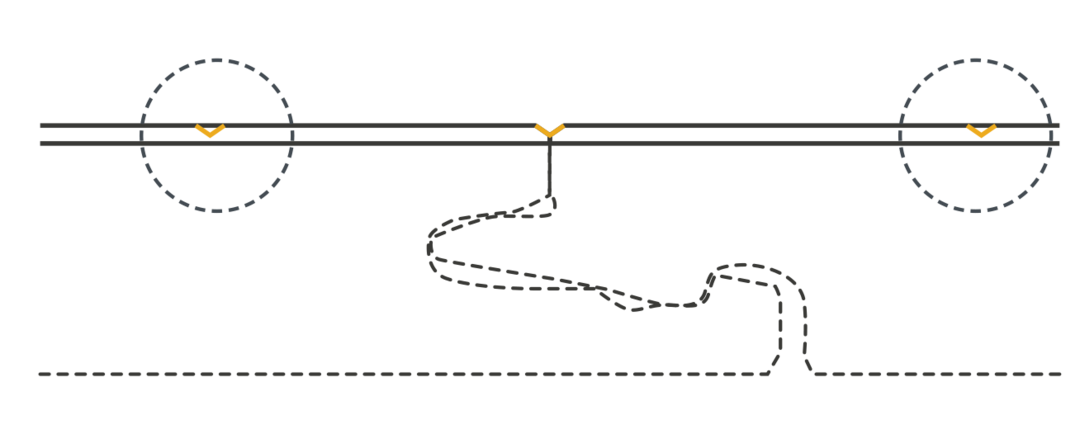

Middle Snit

The Pressed Bevel technology evolved to incorporate the middle snit milling for tiles or herringbone simulations.

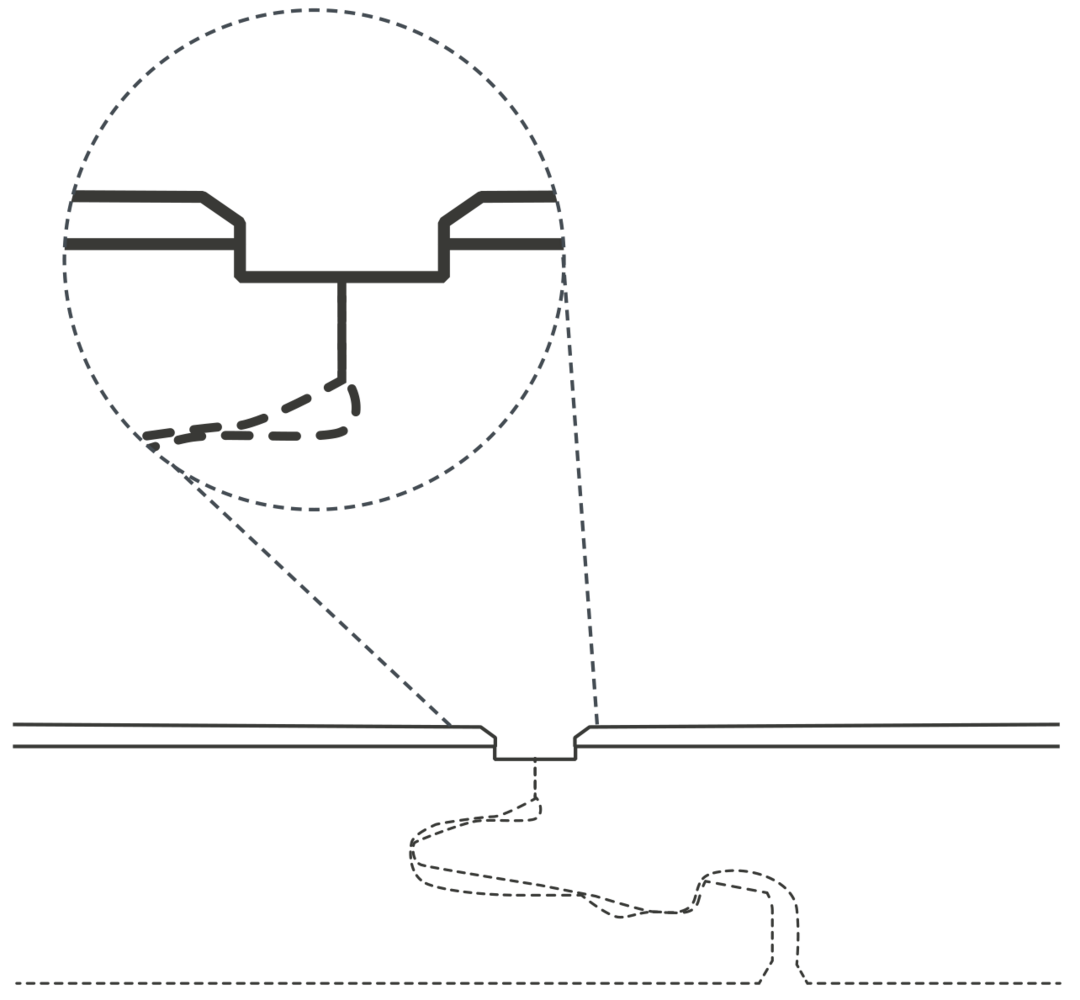

Generation 3 - Pressed Bevel

Pressed Bevel

The beveled edge is created by pressing down the the decor layer so that the decor layer and structure continues all the way to the deepest point of the bevel.

This gives the floors a high end look that is closer to real wood. Unilin patented this process.

Irregular bevel

The pressed bevel technology for resilient flooring is still evolving adding special effects and shapes.

Irregular bevel is a perfect example – it gives a realistic authentic look to the floor.

Generation 4 - Grout

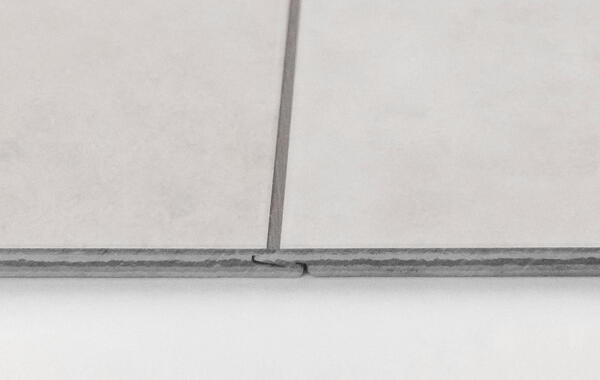

FlinTile Bevel

The FlinTile bevel is a groutable locking system for rigid composite tiles with real grout.

This ceramic alternative creates joints that are are 100% waterproof. The floating installation is possible on existing floors.

The installation is clean and DIY-friendly and can be walked on in less than a day.

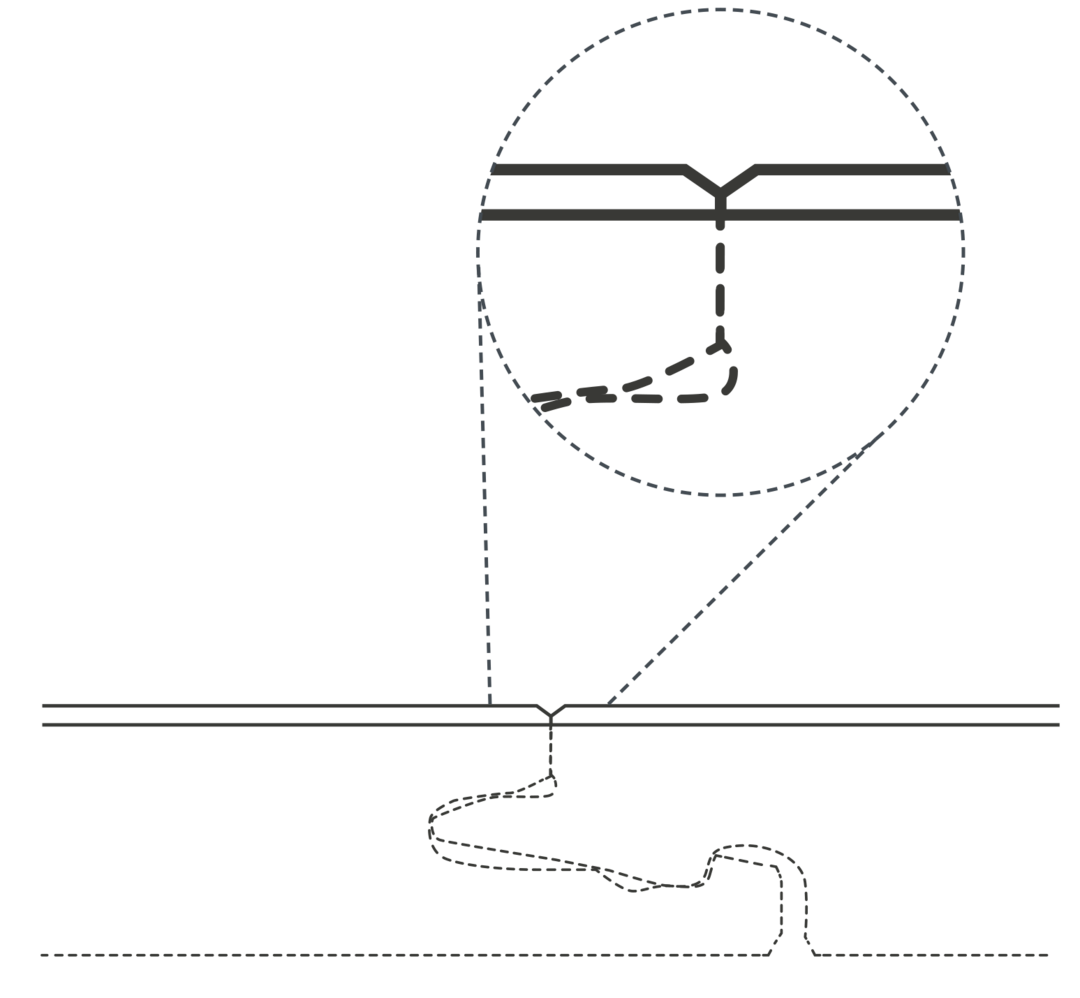

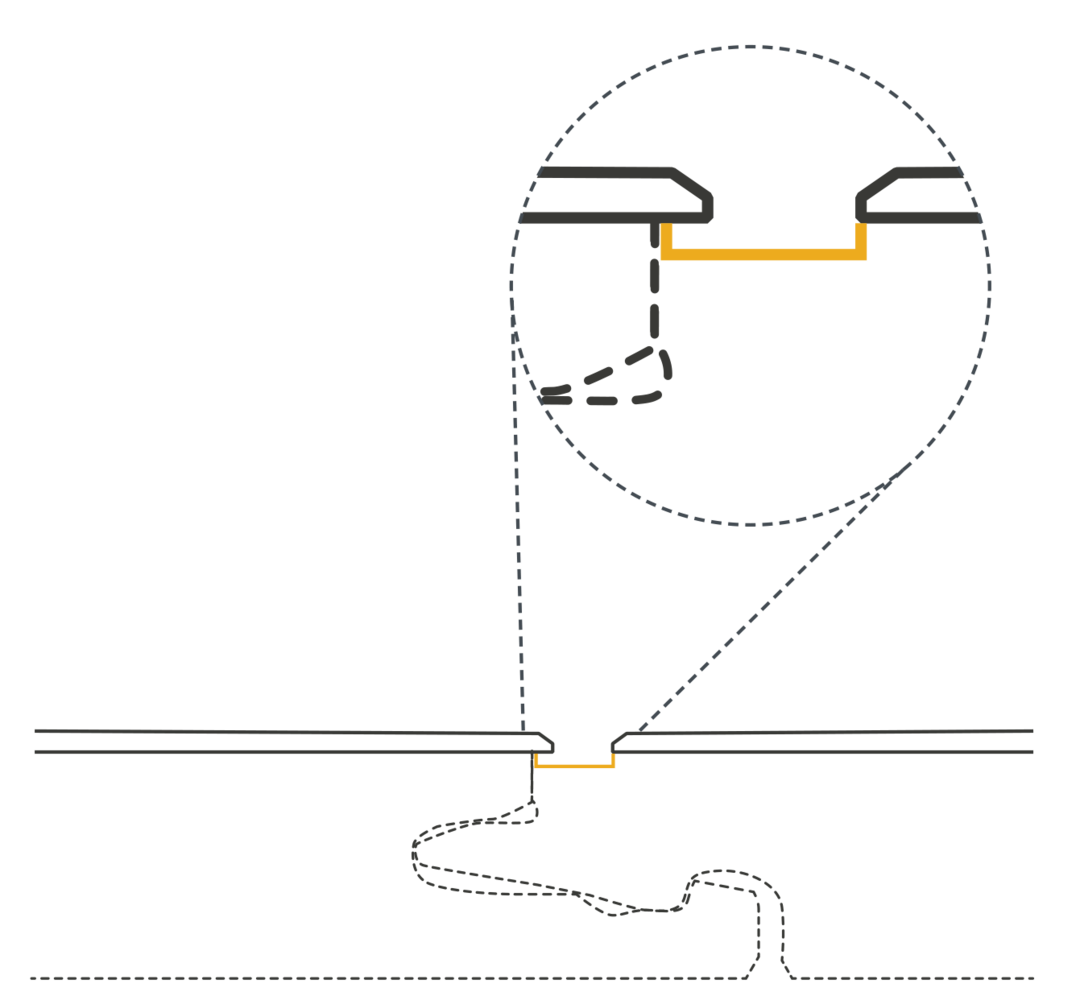

Unigrout Bevel

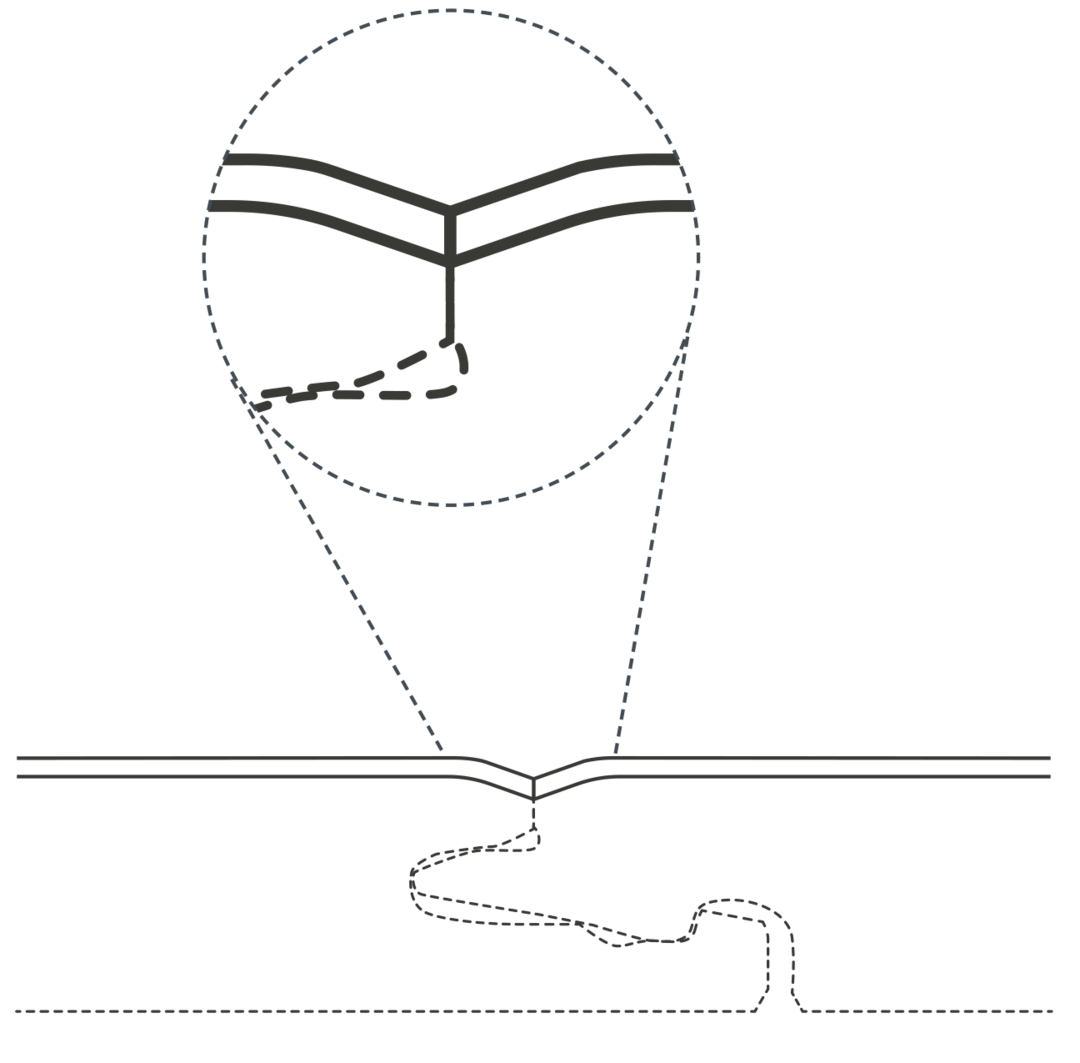

Unigrout is a specific bevel for the edges of rigid tiles that looks exactly like a grouted groove and which is almost indistinguishable from real grout. With the overlapping area underneath the bevel, floor panels can move or expand without showing unwanted gaps.

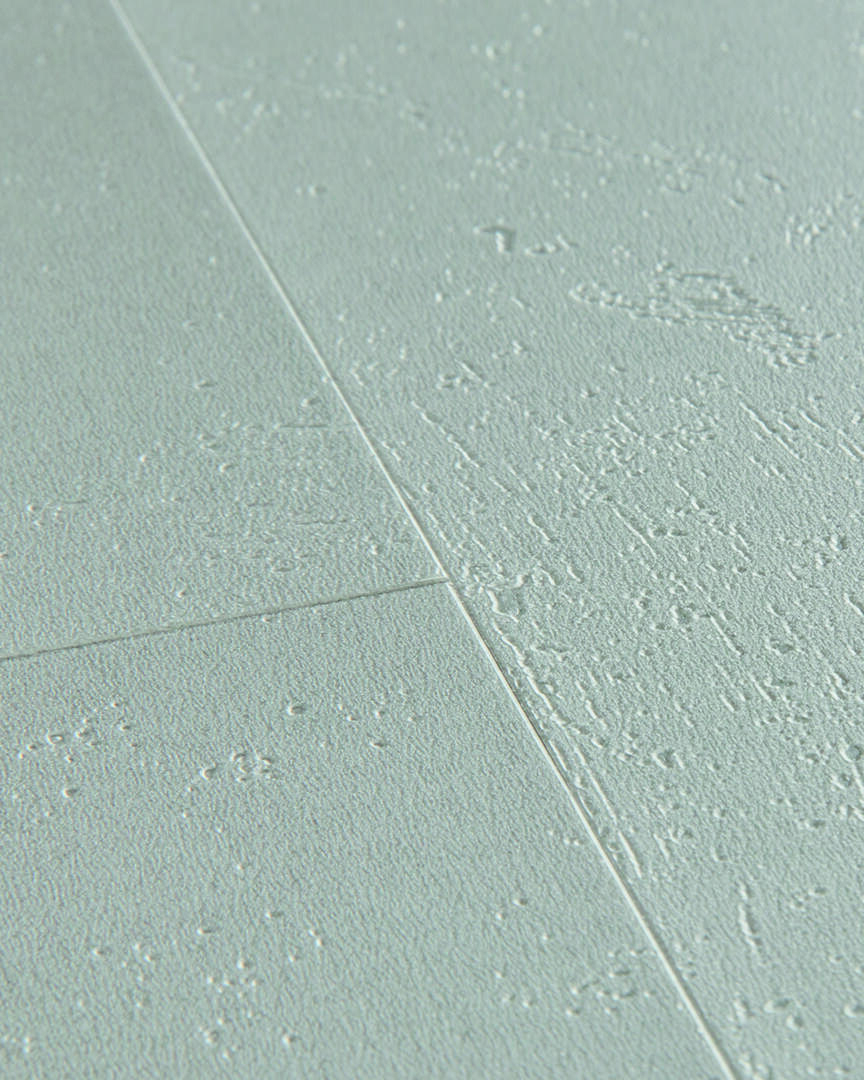

Generation 5 - Matte Bevel

Matte Bevel

Matte Bevel technology is an upgrade of the Micro Bevel and offers a more realistic and natural looking bevel machined in the wear layer.

The special milling technique can easily be integrated into existing milling machines and results in a matte bevel in the wear layer, whereas the traditional Micro bevel has a shiny finish.

The matte bevel has many advantages:

- Low investment & easy to integrate – just exchange the tool

- Suitable for all thermoplastic wear layers (SPC, LVT, WPC)

- Natural appearance

- Reliable – guaranteed same quality